Benefits Of 3D Printing

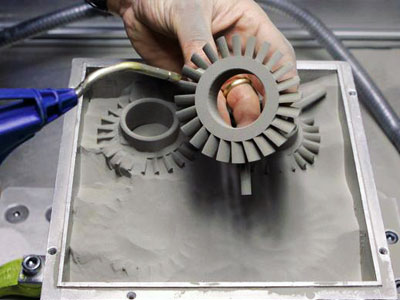

Producing parts through 3D Printing offers many benefits over the traditional manufacturing techniques. It may not replace many of the traditional manufacturing methods yet, but there are applications where a 3D printer is able to deliver value in terms of producing a design quickly, with the high accuracy from a functional material and still be cost efficient.

Get a Quote +91 9900003300FREEDOM OF DESIGN

The restrictions imposed by traditional manufacturing on design, what can be made are generally not relevant for additive manufacturing. The freedom of design is especially valuable, as it also eliminates the additional fabrication design and processes that can take time and cost money. Understanding these advantages of 3D printing allows designers to make better decisions that results delivery of the optimal product.

CUSTOMIZATION

Industries use mass-production to manufacture their products. This means that all products use the same mould and will come out with similar shape and design from the assembly line, which makes it difficult for one to be unique. However, with 3D printing, you can personalize anything by tweaking a part of the prototype, so it can cater your needs. For instance, customizing 3D prints are used in medical and dental industries.

3D printing offers the user the freedom to personalize anything without additional cost. In this way, people can set themselves apart when it comes to fashion or jewelry or even save on costs by efficient designs.

COST ADVANTAGE

Additive manufacturing is very competitive compared to traditional manufacturing at low volumes or prototypes. For the production of prototypes that verify form and fit, it is significantly cheaper than other alternative manufacturing methods (e.g. injection moulding) and is often competitive for manufacturing one off functional parts. There are cost savings in machine operation costs, material cost and labor costs for low batch manufacturing.

TIME TO MARKET

Traditional prototype manufacturing requires tooling and machining. Expensive equipment needs to be purchased and labour hired. The whole process may take weeks and even months. The worse part, your first prototype is never your last, you have to redesign it and experience the same struggle again.

It is difficult to build a good business with traditional prototyping because so much time is wasted. With 3D Printing, the end state is realised fast and the sales force have access to the end presentable product to their clients, which is the icing on the cake.

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.