EP-M250

Selective Laser melting (SLM)

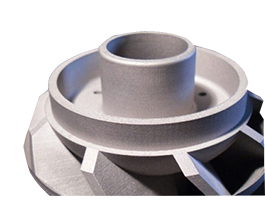

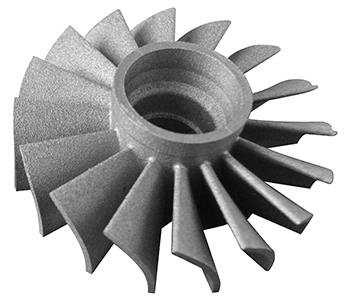

EP-M250 is the latest release of the metal powder material 3D printer, which can prototype an arbitrary complex structure and close to 100% density metal parts without the tools and tooling.

Get a Quote +91 9900003300 Download Product BrochureSelective Laser Melting technology (SLM)

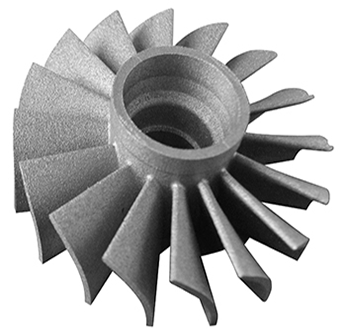

Using the low power laser can directly melt elemental or alloy metal powder material, and can prototype an arbitrary complex structure and close to 100% density metal parts without cutter or tooling.

Material utilization rate is high, making cost lower

The build part forms layer after layer out of powder, and the material utilization rate is over 90%, which is especially suitable for the manufacturing of metal parts, such as titanium alloy, nickel alloy and other precious and difficult-processed metal material.

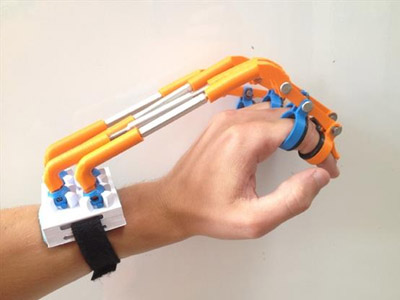

Wide Application

EP-M250 has wide application in aerospace, biomedical, automotive, and home appliance etc.

Model : EP-M250

Material : Stainless steel, maraging steel, high temperature nickel base alloy, titanium alloy, Cobalt chromium alloy, aluminum alloy, high strength steel, copper alloy, tungsten alloy.

Build Volume : 262*262*350mm

Laser Power : 200 w/500 w

Scanning System : 8 m/s

Control Software : Eplus 3D printing software

Scanning Speed: 5 m/s ( max )

OS System Support : Windows 7

Air Supply : Ar / N2

Power Supply : 380V, 26A, 50/60Hz, 10KW

Output Data Format : STL or other convert ible file

Dimension : 2500 x 1000 x 2100 mm3( L x W x H )

Machine Weight : 1350 kg

Work Temperature : 15-30 ℃

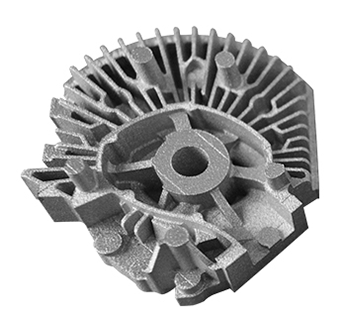

Automobiles

The main driver in 3D printing for vehicles is not printing the entire vehicle, but a move to 3D printing tooling and end-use parts. According to SmarTech, prototyping has only penetrated automotive prototyping by 15% to 20%. Ford, for example, has been 3D printing prototypes for over 20 years to decrease design time.

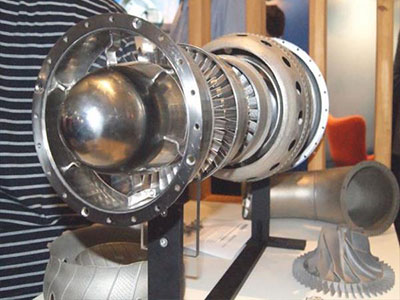

Read MoreAerospace

The aerospace industry is one of the main markets for 3D Printing or Additive Manufacturing. This sector has a long history of early adopters, manufacturers find their needs being fulfilled. Environmental performance restrictions, competitive market conditions and high manufacturing cost are just some of the challenges that aerospace faces today.

Read MoreBatch Manufacturing In Aerospace

Hot Process - No residual stress,No heat treatment. Excellent Material Properties - Controlled microstructure, Better than cast, Compliant with applicable standards. Cost-Efficient Production - High productivity, Material recycling, Competitive powder cost.

Read MoreGeneral Engineering

Architecture

Research & Development

Education

Dental

Casting

EP-M250 SLM 3D PRINTER GALLERY

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.