X1000

Fused Deposition Modeling (FDM) 3D Printer

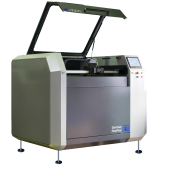

The new X1000 3D Printer is being developed for printing large size objects or multi-object prints in industrial quality. Print protoypes, small series, casting cores or architecture or design objects big, fast and precise.

Get a Quote +91 9900003300Simplify3D Software

One integrated software suite contains everything you need to print high quality parts. Customizable settings and advanced processes put the controls into your hands. Support for dual-extruders, multi-part printing and even multiple processes within one part. Included in scope of delivery.

Large, closed build envelope with safety-door switch:

The closed build envelope avoids poor quality prints due to air flow. An automatic door locking mechanism keeps the hatch closed during the printing process for improved safety.

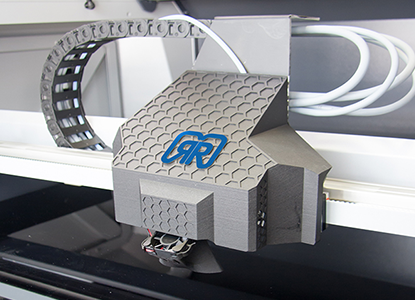

Direct Drive DD3 Extruder with Full Metal Hotend:

New extruder technology, no adjustment neccessary, variable contact pressure. High-heatable hotend (up to 290° C / 554° F) for industrial filaments. Hotends can be exchanged quick and easily.

Print fast and precise

A minimum layer high from 0.1 mm allow precise prints. You just need a draft or a less precise object: Simply use a 1 mm nozzle for quick and fast printing.

Important safety featurer for industrial use

Closed switchboard, emergency shut-down, twofold CO2 fire extinguishing system (optional)

Feature-rich easy to use printing software:

Easy to use printing software with pre-defined printing profiles and many features.

Filament Management:

Two sensor filament control prevents useless prints due to filament run out

File transfer:

Network compatible via Wifi or Ethernet.

Build platform (XxYxZ): 1000 x 800 x 600 mm / 39.4 x 32 x 23.6 in (depending on equipment)

Print speed : 10 – 150 mm/s

Travel speed : 10 – 300 mm/s

Layer height : 0.1 mm

Filament / Nozzle diameter (standard) : 1.75 mm

Power consumption (max.): 2500 W

Operating voltage: 3phase current 400V (CEE 3L+N+PE)

Consumables* : PLA, PVA, PET-G,Carbon20, TPU64D, TPU93, Laywood, Laybrick, ASA, Performance ABS, PC, ESD ABS

Options : Heated print bed, DD3 dual extruder, CO2 fire extinguishing system

Extruder type : Double DD3

Extruder temperature (max) : 290° C / 554° F

File transfer : LC Display with SD card slot, USB, wireless printing via Wifi, Ethernet

Software included : Simplify3D

Weight ca.: 400 kg / 881.85 lbs

Technology: FFF (Fused Filament Fabrication)

Dimensions approx : 1725 x 1500 x 1320 mm / 67.9 x 59.0 x 52 in

Weight approx.: 400 kg / 881.85 lbs

Technology: FFF (Fused Filament Fabrication)

Research & Development

Research & Development is a very crucial part of many industries as well as markets, it has its own benefits. Manufacturers and firms need to ensure that their products constantly evolve and meet the ongoing trends, changing market demands, challenging competition, varying consumer requirements and at the same time be cost efficient.

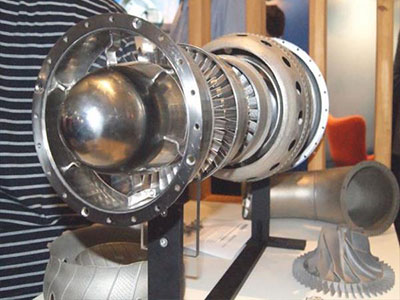

Read MoreAerospace

Automobiles

Education

Medical

Perhaps the most immediate and life-affirming industries currently benefiting from 3D printing are the medical industries. The most common application may be the use of a patient’s medical imaging data, such as a CT scan, to create a 3D-printed medical model.

Read MoreX1000 3D Printer Gallery

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.