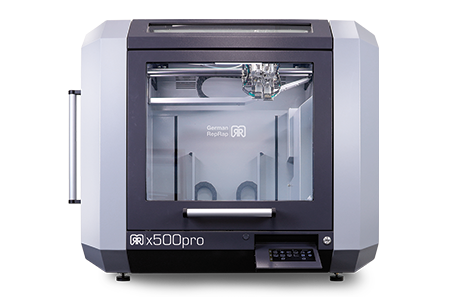

GRR X500 pro Printer

Fused deposition modeling (FDM) |Fused Filament Fabrication (FFF)

Production Grade FFF Printers from German Reprap, these printers are build to perform in 24 x 7 Production Environment to produce the best in class output. With the capability of production with third party filaments, these printers offer a higher degree of ROI and compete with the best production printers in its class.

Get a Quote +91 9900003300 Download Application Notes & PdfThe x500pro is a large-volume 3D printer loaded with all new features necessary for professional use. Print intricate models up to 500 x 400 x 475 mm in size with a layer height of down to 20 microns with engineering grade materials!

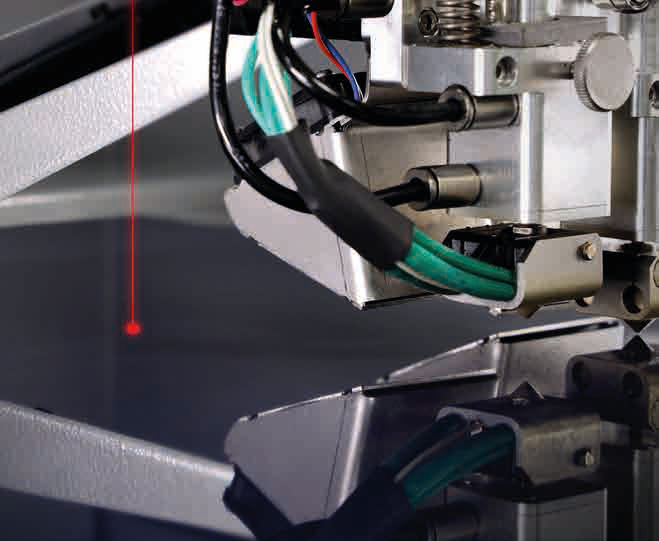

The x500 has been optimized and tested for high precision and accuracy 3D printing in industrial settings. After initial installation and commissioning of the X500, a baseline mechanical accuracy of +/- 0.0015 mm/mm can be expected on printed parts every time.

The x500 is utilized by engineers and materials developers at some of the largest plastics and polymer companies in the world. This is because the x500 is open material 3D printing platform - this means that you have full control of all print parameters and no lockouts to prevent you from working with new materials. Unlike most 3D printers on the market, the x500 comes factory equipped with hot temperature hot ends, a heated build plate and a heated chamber for even the most tricky materials like PEKK, PEI, PC, and PEEK. Whether you want to test out the latest filament from a promising startup or test a proprietary material blend, the x500 is up to the task!

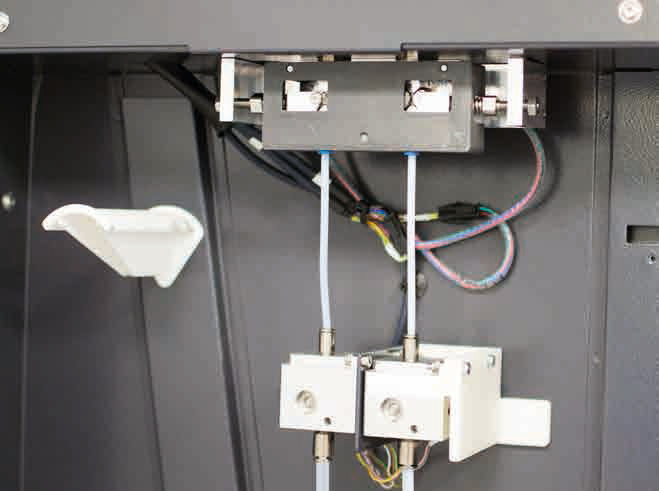

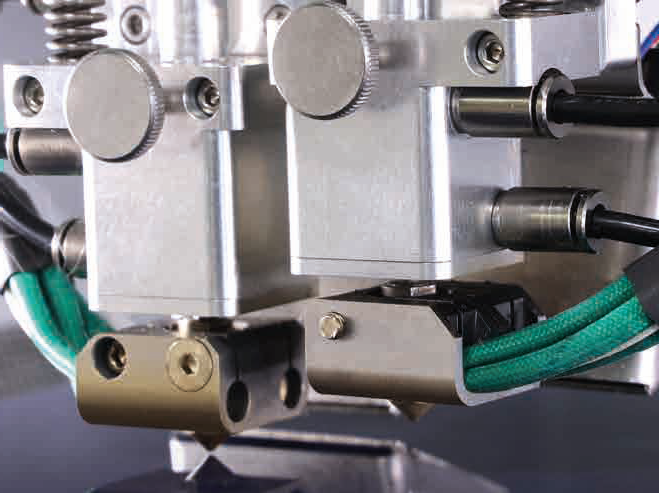

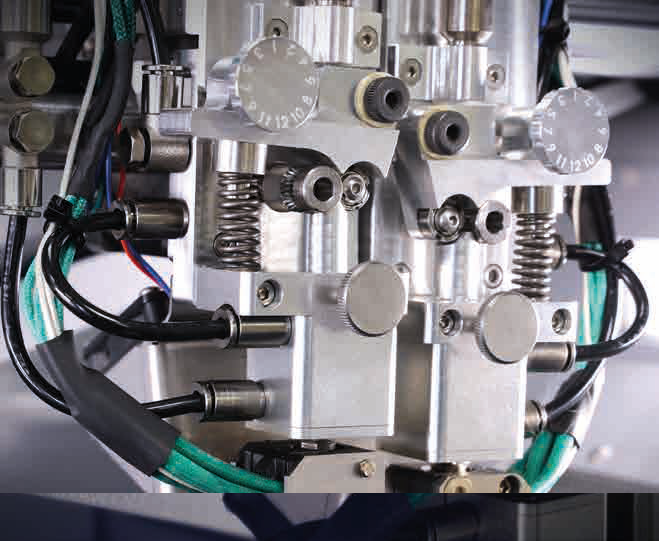

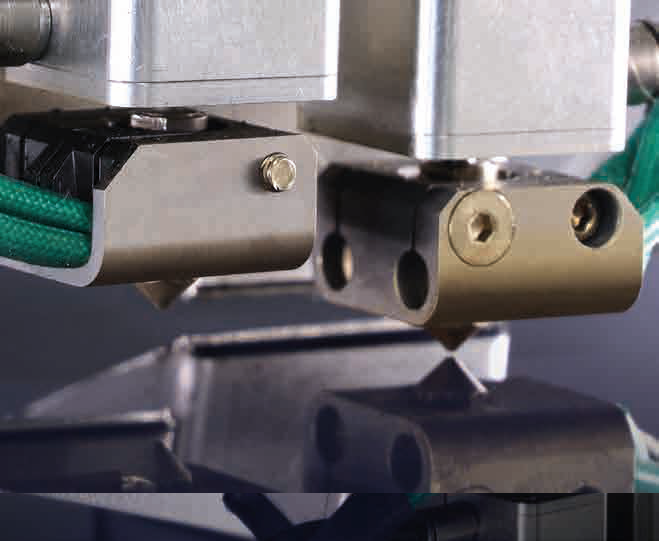

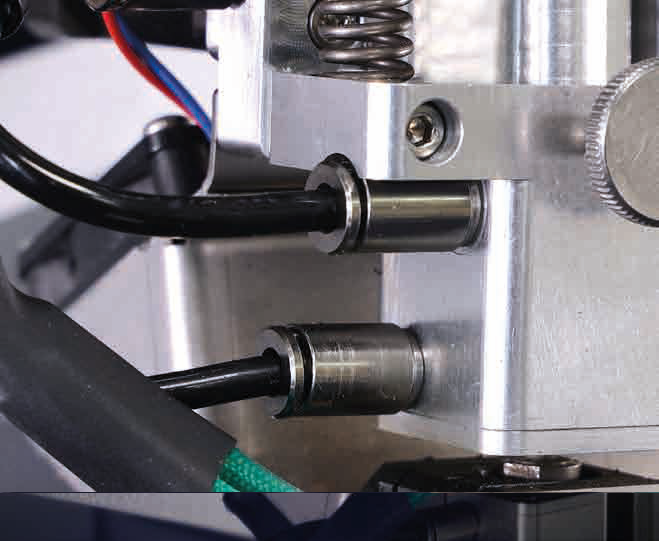

Extruders: DD4 Dual, 1.75 mm

Extruder Temp (Max): 400C / 752F

Resolution (max): 20 microns (0.02mm)

Accuracy: +/- 0.0015 mm/mm

Heated Bed: Ceramic Plate (removable)

Heated Bed Temp (max): 125C / 248F

Heated Chamber: Actively Heated

Heated Chamber Temp (max): 80C / 176F

Build Volume: 500 x 400 x 475 mm / 19.7" x 15.7" x 18.7"

Nozzles : 0.25 mm, 0.4 mm (std), 0.6 mm, 0.8 mm *Available in Brass or Hardened Steel

Speed (max) : 150 mm/s

Materials : Open-Material Configuration, including PEKK-CF, PEI, Nylon (PA), PA-CF, PA-GF, Metal-Fill, ABS, PLA, PVA, PET, HiPS, TPU, Carbon20, Dupont Zytel (Nylon), DuPont Hytrel (Flexible), BASF Ultra fuse (Metal)

Voltage :230V European Standard, Schuko (110V Transformer available)

Power :4400W max

Weight : 375 lbs

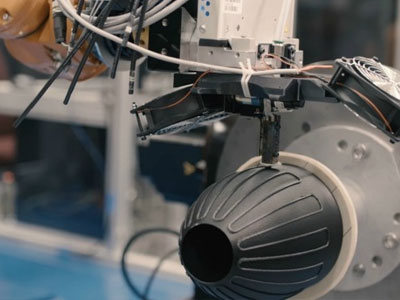

Automobiles

Research & Development

Architecture

Education

General Engineering

When engineering challenging designs, 3D printing let’s you try new prototypes, address problems and find solutions as you go, all in a matter of hours. It also allows you to work with complex internal structures and geometries, something traditional methods just can’t offer.

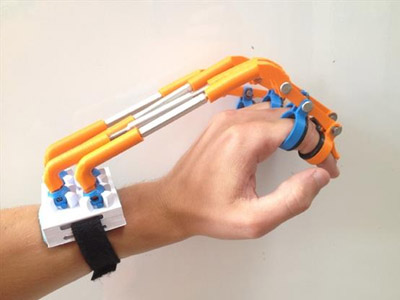

Read MoreMedical

Gaming

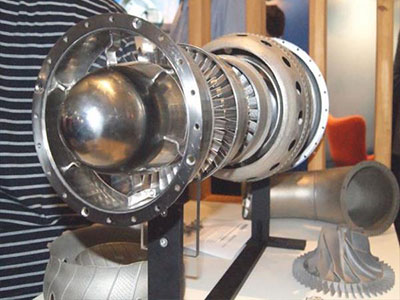

Aerospace

Batch Manufacturing in Aerospace

Batch Manufacturing in Medical

X500 Pro

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.