EBM Industrial 3d Printer

Arcam EBM Q20plus

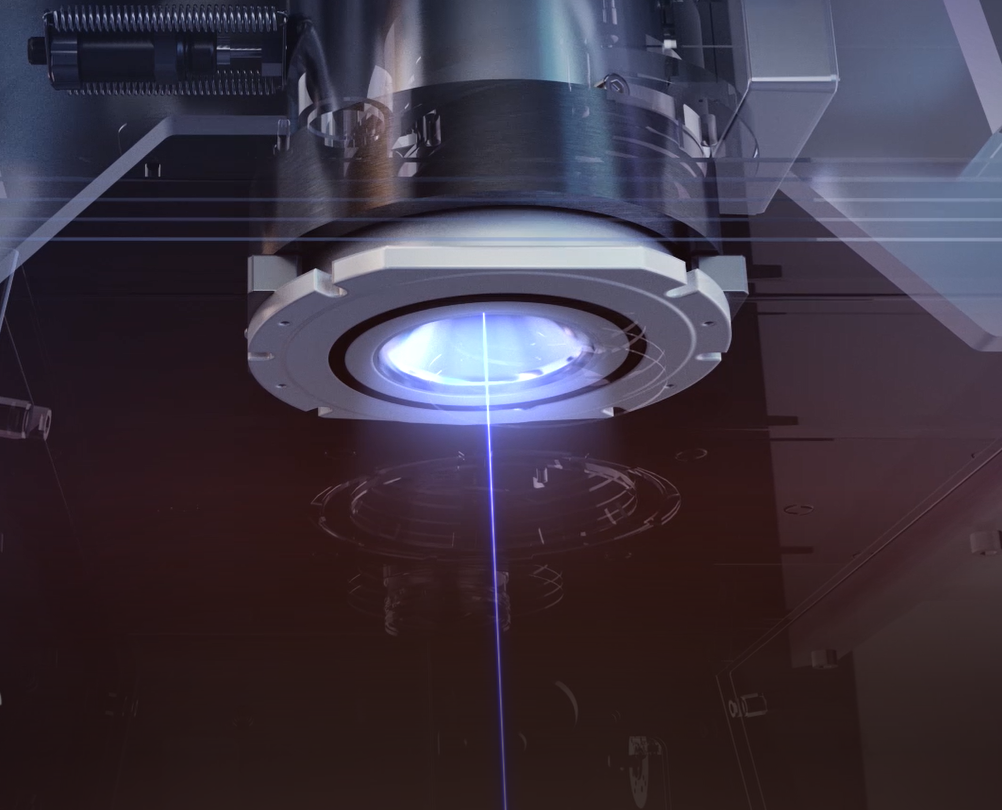

EBM machines from Arcam EBM create dimensionally accurate parts quickly and efficiently by utilizing a high-power electron beam for high melting capacity and productivity. The Arcam EBM process takes place in vacuum and at high temperature, resulting in stress-relieved components with material properties better than cast and comparable to wrought material.

EBM technical paper

Electron beam melting (EBM) technology has the power to help businesses build the next generation of applications, today. Offering high productivity and lower cost per part, EBM is an innovative technology for manufacturing in the orthopedic implant and aerospace industries.

Electron Beam Melting (EBM 3D Printing) of titanium in real time - Arcam Q20 Plus

Arcam EBM Q20plus

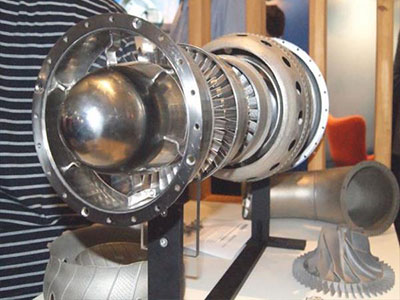

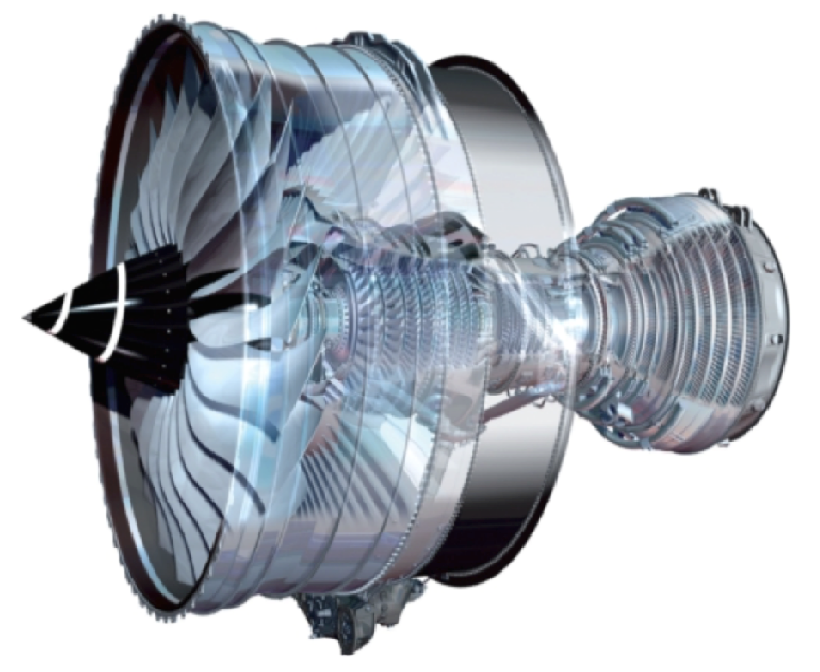

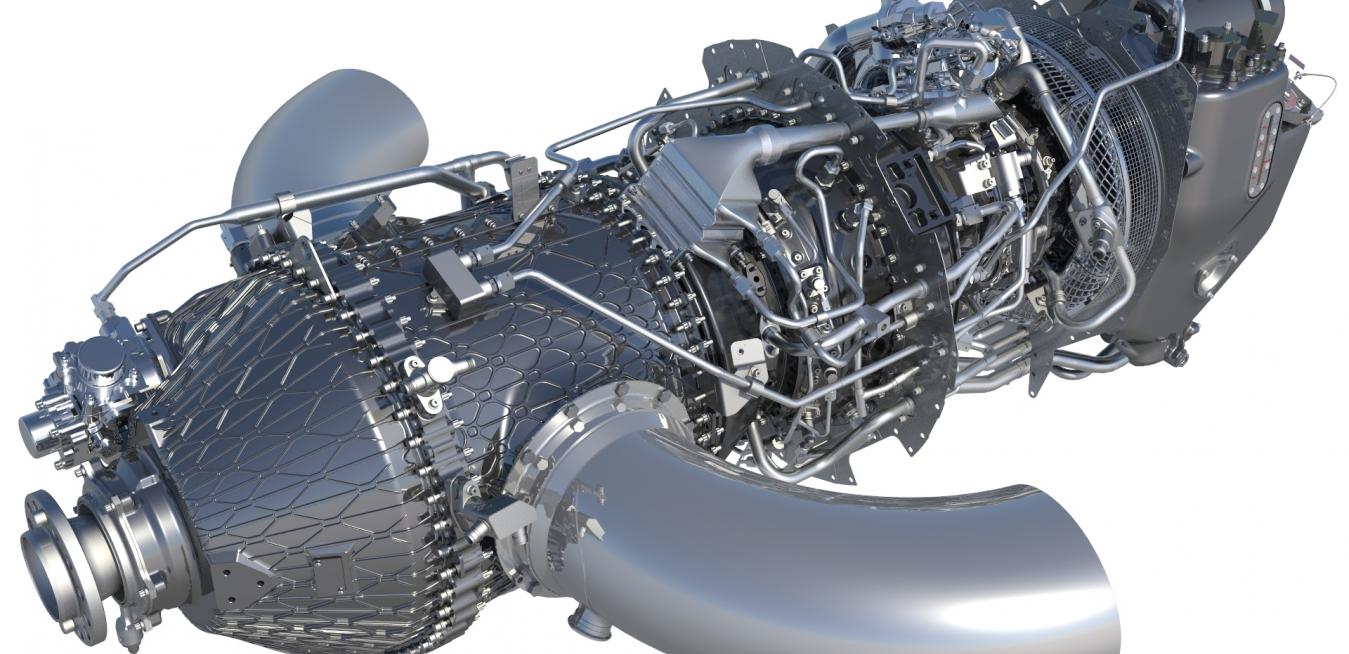

The Arcam EBM Q20plus is specifically designed for cost-efficient production of aerospace components, such as turbine blades, structural airframe components and much more. The build envelope allows for building large components and optimal stacking of smaller ones. The build chamber interior is developed for easy powder handling and fast turn-around times.

The Arcam EBM process takes place in a vacuum and at elevated temperatures, resulting in stress relieved components with material properties better than cast and comparable to wrought material.

The machine includes Arcam EBM xQam™ technology for high precision autocalibration, a powerful software platform and electronics for efficient and accurate beam control. It also features Arcam EBM LayerQam™, a camera-based monitoring system for part quality control. The Arcam EBM Q20plus can be delivered with a powder recovery system for efficient powder handling.

Electron Beam Power

3 kW

Build volume

350 x 380 mm (Ø/H)

Highlight:

- Arcam EBM xQam™ for high precision autocalibration

- Arcam EBM LayerQam™ for part quality control

- Efficient powder handling

Available Materials:

- Arcam EBM Ti6Al4V Grade 5, P-Material

- Arcam EBM Ti6Al4V Grade 23, P-Material

Higher Productivity

In addition to enhanced precision and process robustness, Arcam Q20plus offers high productivity. This is made possible by many important new features, including ground-breaking Arcam xQam technology for high precision auto calibration, a powerful new software platform and electronics for efficient and accurate beam control.

Cost reduction

Finding ways to reduce weight is key in the aerospace industry. So is cost reduction. Of particular interest is the so-called Buy-to-Fly ratio — the weight ratio between the raw material used for a component and the weight of the component itself. Ratios as high as 15-20 for flying components are common, adding a lot of cost to the component for material and machining. The Arcam EBM® process opens up exciting opportunities to produce lightweight components with a Buy-to-Fly ratio very close to 1.

Shorter lead times

Aerospace companies often have to rely on a few dominant suppliers for traditional casting of components, and the lead-time for design iterations can be many months. Since Arcam EBM® technology is a tool-less production technology, it allows design modifications to be made with minimal lead-time and cost.

New design possibilities

The freedom in design provided by Arcam EBM® technology enables designers to create completely new and innovative product designs. Components can be optimized in terms of weight reduction or functional aspects such as improved cooling, heating or filtering characteristics.

Easy-to-use operator interface

Latest generation EB Gun for high productivity and surface finish

Arcam EBM xQam™ for high precision auto calibration

Arcam EBM LayerQam™ for build verification

Software adapted to volume production

-

Max. build size : 350 x 380 mm (Ø/H)

-

Max. Beam power : 3000 W

-

Cathode type : Single crystalline

-

Min. Beam diameter : 140 μme

-

Max. EB translation speed : 8000 m/s

-

Active cooling : Water-cooled heat sink

-

Vacuum base pressure : 5 x 10-4 mbar (chamber pressure before start of process

-

Build atmosphere : 4 x 10-3 mbar (partial pressure of He)

-

He consumption, build process : 4/1 liter / hour

-

He consumption, build cool down : 100-150 l/build

-

Power supply : 3 x 400 V, 32 A, 7kW

-

Size : 2400 x 1300 x 2945mm (W x D x H)

-

Weight : 2900 kg

-

CAD interface Standard : STL

Batch Manufacturing In Aerospace

Hot Process - No residual stress,No heat treatment. Excellent Material Properties - Controlled microstructure, Better than cast, Compliant with applicable standards. Cost-Efficient Production - High productivity, Material recycling, Competitive powder cost.

Read More

Automobiles

The main driver in 3D printing for vehicles is not printing the entire vehicle, but a move to 3D printing tooling and end-use parts. According to SmarTech, prototyping has only penetrated automotive prototyping by 15% to 20%. Ford, for example, has been 3D printing prototypes for over 20 years to decrease design time.

Read More

General Engineering

Aerospace

The aerospace industry is one of the main markets for 3D Printing or Additive Manufacturing. This sector has a long history of early adopters, manufacturers find their needs being fulfilled. Environmental performance restrictions, competitive market conditions and high manufacturing cost are just some of the challenges that aerospace faces today.

Read MoreArcam Q20plus Gallery

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Additive Benefits for the Medical and Orthopedic Industry

Design freedom for medical implants

Additive Manufacturing provides you the flexibility to customize the implant for patient needs, achieve desired mechanical properties, and ease surgery.

Medical implant complexity

You can add features to increase functionality and effectiveness of the implant without increasing production steps or costs.

Mechanics of the body

You can design porosity and pore size, as well as interconnectivity of trabecular structures to allow for enhanced initial fixation and bone ingrowth.

One medical implant

AM enables integrated trabecular structures that reduce risk of delamination and simplify the supply chain because the implant is made in one step—and one part.

Flexible and efficient production

AM is suitable for both serial production and manufacturing of mixed implant designs and sizes, without the need for change in hardware configuration. This allows for minimal waste and high productivity.

Applications

Low Pressure Turbine Blades

Landing Gears

Nozzles

Engine Components

B2B 3D Printers and 3D Printing Solutions

Incorporated in the year 2013, Lodestar Innovations Pvt. Ltd. is a professional company engaged in providing B2B 3D printers and 3D printing solutions to specialized industry verticals such as Aerospace & Defense, Jewelry, and Medical & Engineering.

With the necessary licenses to Import, Sell and Service Industrial Grade 3D Printers, the team at Lodestar Innovations Pvt. Ltd. has the experience and thorough understanding of what exactly are the needs of their clients and the recommended solutions are customized to their specific requirement. Further, our engineers have more than 15 years hands on experience on industrial scale 2D printers and 3D printers.

Prior to establishing the company, the promoters have had extensive experience in selling high value capital equipment with companies like Agfa, Efi, Oce, Canon etc and also have led some established MNCs at international levels. We have more than 100 installations around the world.

Our team will assist you with the installation process. We stand behind our high precision 3D printers and are here to support your success. Every 3D printer comes backed by our unmatched customer service and a global network of technical support specialists.

Contact us for printer, application, installation or support.

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.