- Home

- 3D Printers & AM Systems

- Arcam EBM Q10plus

- Arcam EBM Spectra L

- Arcam EBM Spectra H

- EP-A350 Resin (SLA)

- EP-A450 Resin (SLA)

- EP-A650 Resin (SLA)

- EP-A800 Resin (SLA)

- Lodestar S300

- Lodestar S400

- WaxJet 400

- WaxJet 410

- Sharebot Desktop System

- TPM P260

- TPM P360

- TPM P550

- TPM P320 HT [PEEK]

- EP P420 SLS 3D Printer

- EP P3850 SLS 3D Printer

- PCM 800

- PCM 1200

- PCM 1800

- PCM 2200

- EP-C5050

- EP-C7250

- EP-M150 [single/dual laser]

- EP-M260 [single/dual laser]

- EP-M300 [single/dual laser]

- EP-M450 [dual/quad laser]

- EP-M650 [dual/quad laser]

- EP-M150 Dental [single/dual laser]

- EP-M150 Pro [single/dual laser]

- Sharebot Metal One

- FUNMAT HT

- FUNMAT 410 PRO

- FUNMAT PRO 610 HT

- InnovatiQ X 500 Pro

- Slash 2 +

- Uniz NBEE

- Shinning 3D AccuFab-L4D

- NXE 200

- NXE 400

- XiP

- NXD 200

- QLS 820

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

Binder Jet/PCM (Sand Casting)

Investment Casting

Metal 3D Printers & AM Systems (Laser)

FFF/Filament (FDM) 3D Printers & AM Systems

High Precision Dental 3D Printer

Nexa 3D Printers

- 3D Scanner/3D Digitizing Solution

- FreeScan Trak

- FreeScan UE Pro

- FreeScan UE

- Autoscan Inspec

- RobotScan E0505 Robot Automatic 3D Scanning System

- OptimScan-5M Metrology 3D Scanner

Portable Wireless Optical Coordinate Measuring System

High Precision Laser Handheld 3D Scanner

High-Precision 3D Inspection Scanner - Software

- Applications

- Material

- Company

3D Printers & AM Systems

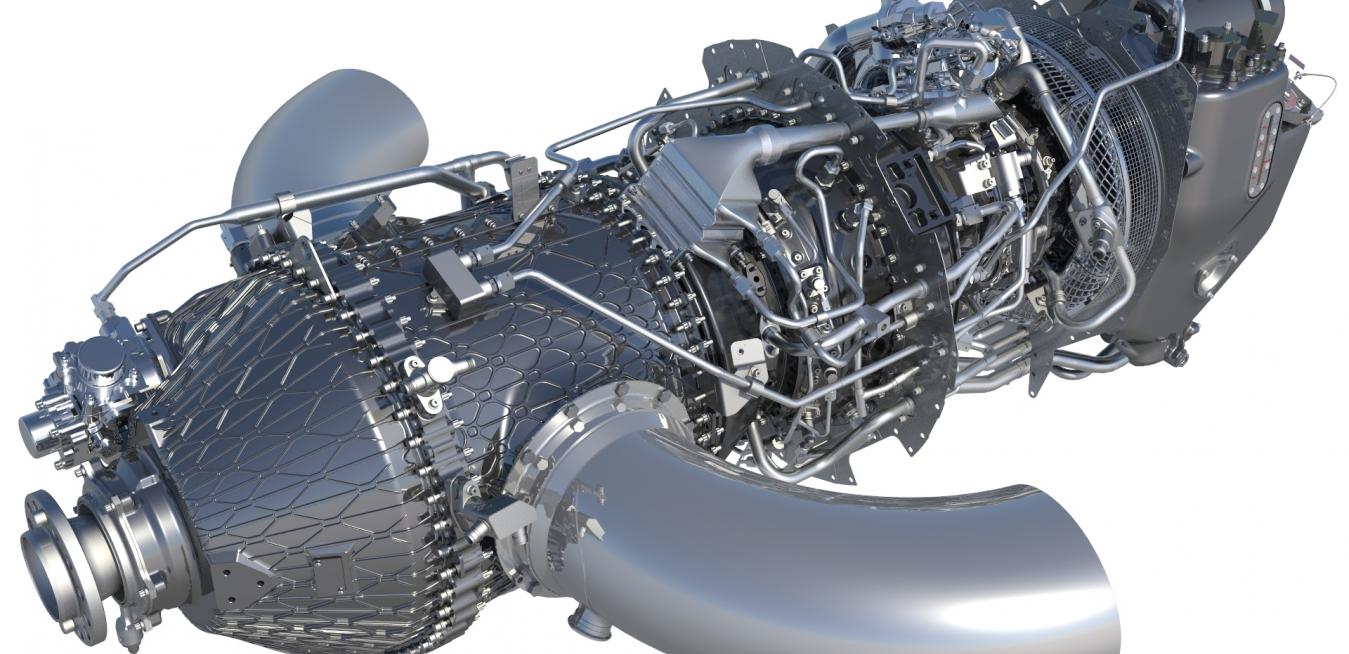

EP-M650 Metal 3D Printer

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655 x 655 x 800 mm build envelope and four laser systems to ensure a high efficiency printing production. The precise positioning and innovative area splicing control technology hereby offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Die Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is siutable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

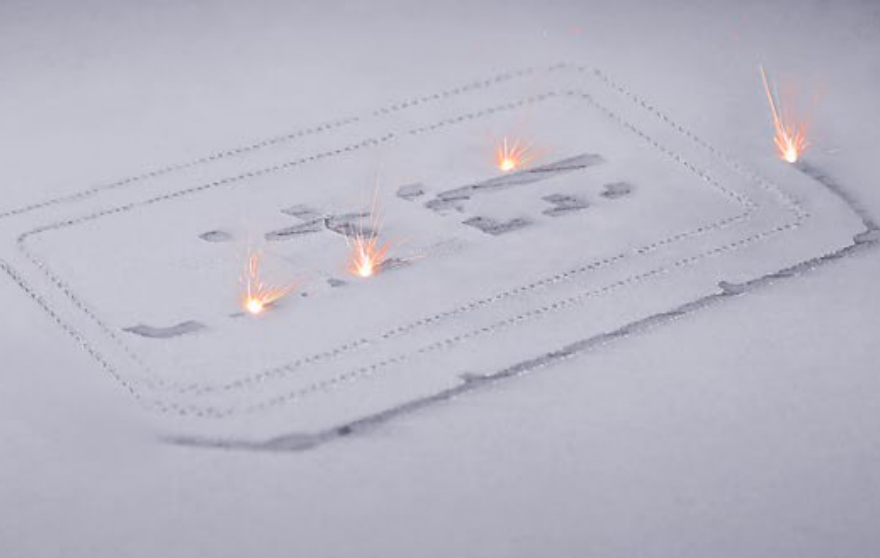

High Efficiency & Productivity

Printing of mass-individualized parts in the 340 Liter (655 x 655 x 800 mm) build chamber.

Four lasers are printing simultaneously with up to 120 cm3, which is an increased efficiency of 3.5 times compared to a single laser system.

Printing large layer thicknesses of more than 60 um possible.

Stable Quality, Good Consistency

High parts accuracy in the overlap area of 0.1 mm. The deviation of mechanical properties compared to a single laser system is lower than 3%.

Optimized design the air flow ensures the effective removal of dust and splatter as well as a unifrom parts quality in the whole print bed.

The strict calibration ensures the consistency between parts and batches.

Humanized Design, High Automation Degree

Friendly user interface with fully automatic one-click printing funciton.

The buildjob information is displayed in real time with traceable prinitng parameters and a detailed printing report.

The one-piece take out function ensures a high automation and low down time, due to an automatic movement of the building cylinder into the cleaning module after the print is finished.

Real Time Monitoring, High Security

Safety design, prevent misoperation, electric shock, fire, waste and pollution.

Outstanding overall sealing performance, use and recovery of powder in a closed state.

Environment and gas source state Real-Time Monitoring, safe and reliable.

Perfect After-sales Service

We support our customers with technical consulting services, including data evaluation, application development.

Assisting our customers in new material parameter development. Existing parameter packages are provided free of charge.

Free equipment installation and maintenance during warranty period, full set of technical training is provided.

EP-M650 Metal 3D Printer Parameter

Machine Model : EP-M650

Build Volume (XxYxZ) : 655x655x800mm³

Optical System : Fiber Laser4*500W

Spot Size : 90-130µm

Max Scan Speed : 8m/s

Layer Thickness : 20-120µm

Building Speed : 120cm³/h

Material : Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel,Stainless Steel, Cobalt Chrome, Copper Alloy, etc.

Substrate heating : Substrate heating temperature 200℃

Power Supply : 380V, 3P/N/PE, 50 / 60Hz, 25kW, 65A

Gas Supply : Ar/N2

Forming chamber oxygen content : ≤100ppm

Dimension (WxDxH) : 5880*3840*3630mm³

Weight : 15000kg

Software : EP-Hatch ,EP Control

Input Data Format : STL file or other convertible format

EP-M650 Metal 3D Printer Gallery

Read

Latest News

XJet Partners with Straumann to Boost Ceramic AM from Concept to Production - MANUFACTUR3D Read More

Legendary Damascus steel 3D printed by varying temperature of layers Read More

3D Printing in Education Market 2020 In-Depth Analysis of Industry Share, Size, Growth Outlook up to 2025 Read More

Ceramic 3D Printing Market Manufacturer Analysis and Segmentation from 2020-2026 | 3D Cream, Admatec, Emerging Objects Read More

Electron Beam Melting (EBM) Systems

SLA Systems (VAT Based Industrial Grade)

High Precision Wax : MJP

SLS (Polymer) Systems

High Precision Dental 3D Printer & AM Systems

Metal 3D Printers & AM Systems (Laser)

FFF/Filament 3D Printers & AM Systems

Copyright © 2024 Lodestar Innovations Private Limited. All rights reserved.